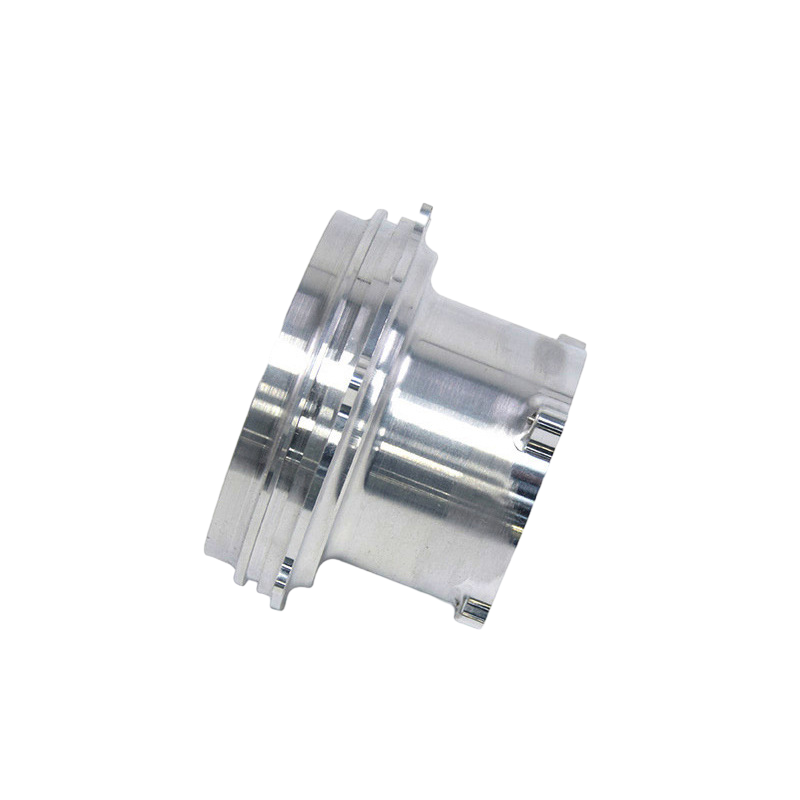

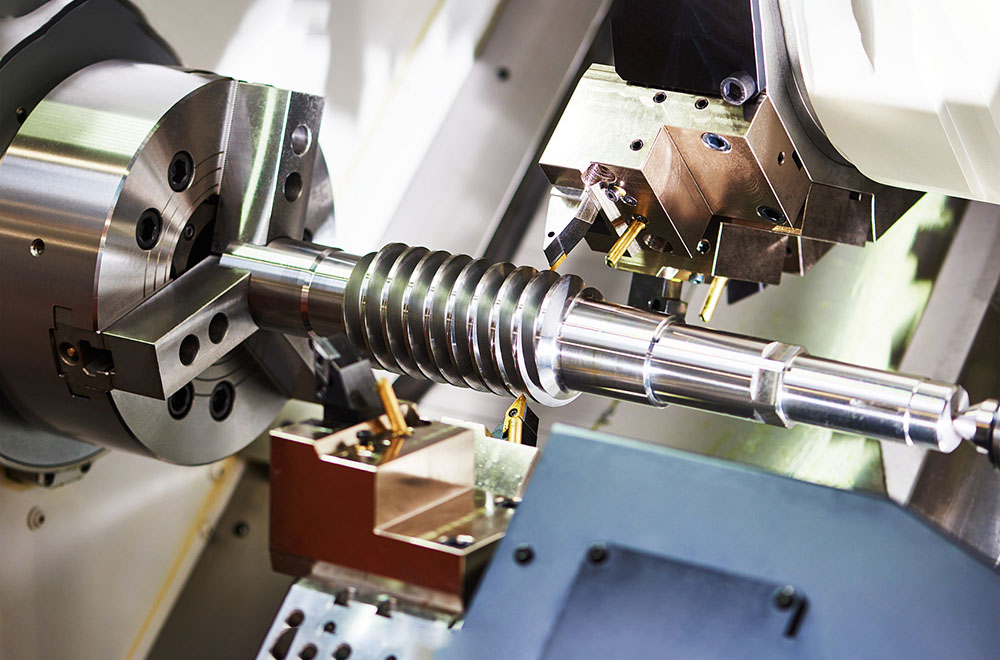

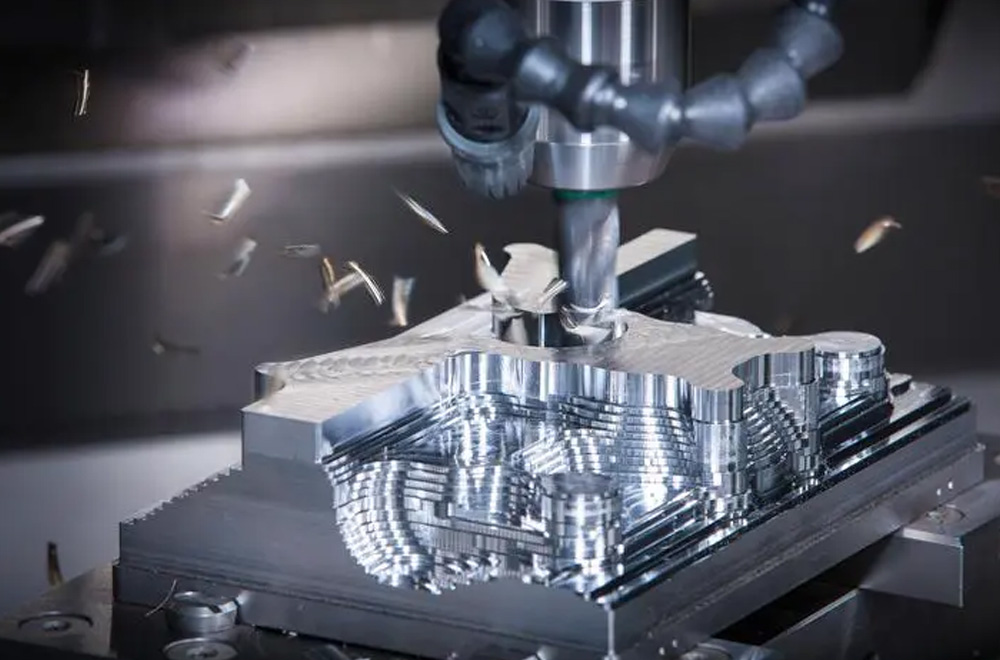

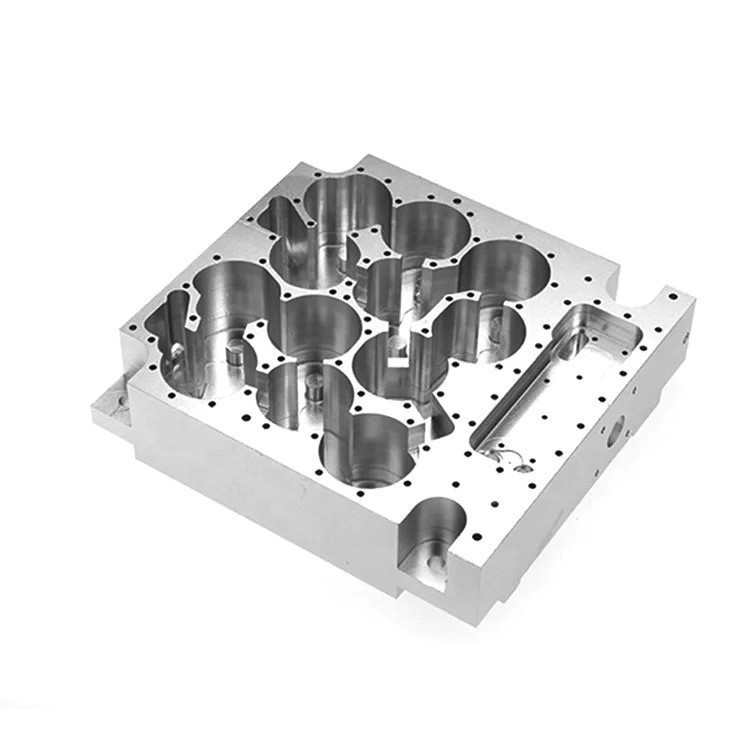

CNC precision machining aluminum alloy new energy vehicle steering wheel converter seat 4-axis 5-axis anodic treatment can be customized

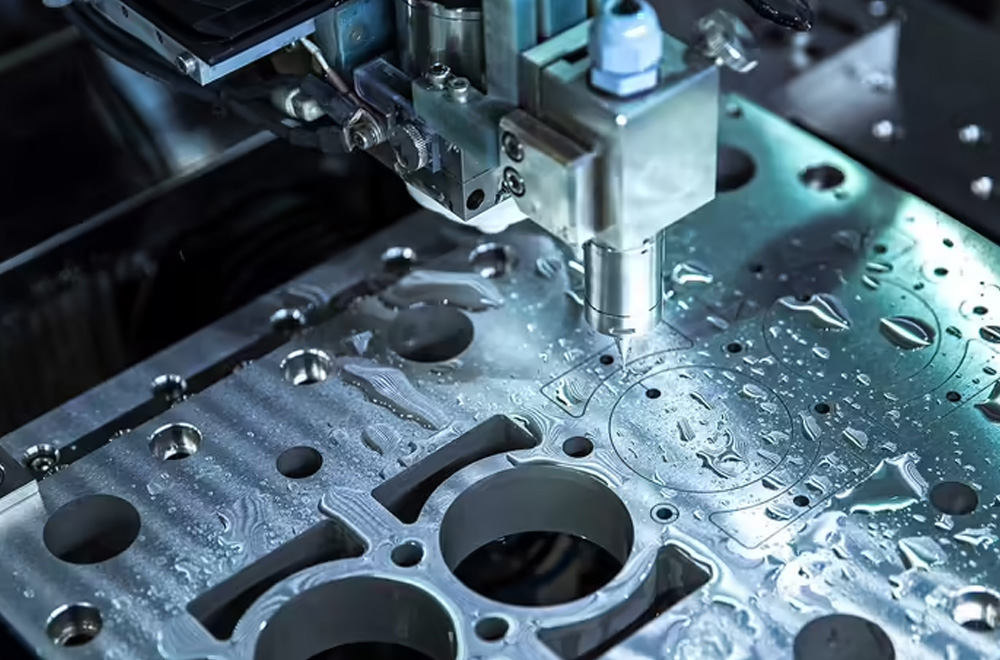

The corrosion resistance of aluminum alloy is one of its important chemical properties. The surface of aluminum alloy is prone to form a dense oxide film, which can effectively prevent further corrosion of aluminum alloy, so that it can maintain good performance in harsh environments. In the machining process, it is necessary to consider this characteristic and select the appropriate cutting fluid. For example, water-soluble cutting fluid containing rust remover or corrosion inhibitor can not only meet the requirements of aluminum alloy material plasticity on the lubrication and cooling effect of cutting fluid, but also reduce the corrosion of aluminum alloy to ensure the processing quality. At the same time, when welding aluminum alloy, it is also necessary to consider its chemical properties, take appropriate process measures, such as surface pretreatment, etc., to improve the aluminum alloy to the laser absorption rate, reduce the generation of porosity and other welding defects.